Overview

![]() Particle sizing & characterization

Particle sizing & characterization

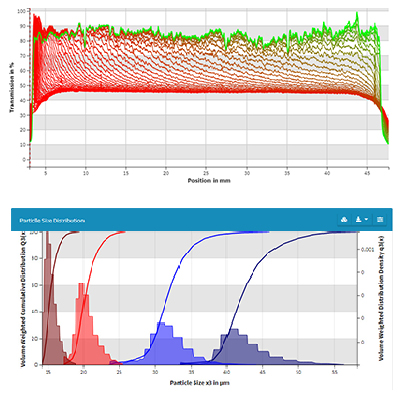

Frequently optical particle size measurement techniques are used to determine the volume weighted distribution. To this end the size and material dependent extinction coefficient is needed, which can be calculated by Mie-theory using known complex refractive index of the particles. In this case strong assumptions have to be made like spherical homogeneous particles. The experimental determination of the refractive index can be very difficult especially in the submicron range and for heterogeneous particles. No standard methods are available today.

The evaluation of space and time resolved extinction profiles for separating particles at different wavelengths can be used as alternative approach. The information on particle size distribution is then gained from sedimentation or creaming velocity and the wave length dependency of the extinction. The extinction coefficients and further the volume weighted particle size distribution can be calculated based on the differences between the profiles by algorithm described.

Reference: bit.ly/2mqKbqU

![]() Droplet size & particle size distributions

Droplet size & particle size distributions

Particle sizing for the whole sample:

- STEP-Technology

- True raw data – Direct physical measurement

- Same principle applied for nm to µm

- High resolution for multimodal systems

- Higher concentrations possible than for other

techniques - Closed sample cell – No restrictions for liquid

continuous phase

![]() Stability testing & separation analysis

Stability testing & separation analysis

LUMiReader PSA is used in countless applications for direct real-time stability testing and separation analysis of emulsions, suspensions, suspoemulsions and related products in their original concentration.

The measuring temperature is selected according to the application and storage conditions from the large range between 4-80 °C. Advantages are reported for nano & microparticles, for unsteady particle systems like crystals and their agglomerates, fibres and flakes. A sample specific acceleration of the separation at gravity can be achieved by inclined settling, applying the Boycott effect.

References: bit.ly/2mt2GuP & bit.ly/2kO0PAq

![]() Aging, particle size & concentration changes

Aging, particle size & concentration changes

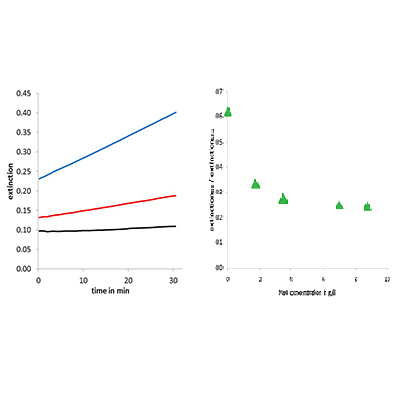

LUMiReader PSA measures extinction profiles at different wavelength. This allows for the determination of changes in concentration and/or particle size. The differences at different wavelengths can be used for the comparison in product quality. Changes in particle size may result from flocculation, coalescence, etc.

From the separation velocity, the light attenuation and the signal differences at different wavelengths the extinctions coefficients and further the volume weighted particle size distribution can be calculated using the Multiwavelength Extinction Ratio analysis module in SEPView software. No complex refractive index is needed and strong assumptions like spherical homogeneous particles are not necessary.

Reference: bit.ly/2mSotfS

![]() Quality control

Quality control

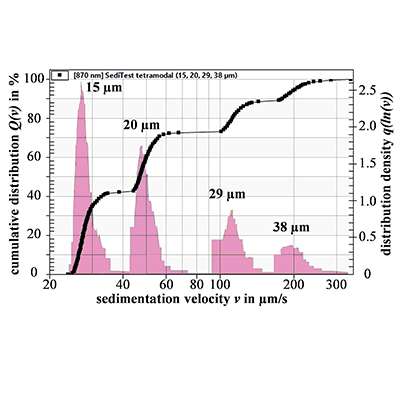

Quality control is the essential part for producing satisfying products. This relates to the control of the raw materials, intermediate and final products. For dispersion related products there might be changes in particle size of a single component, of the whole system or in

material composition, which would affect the quality of the final product.

Therefore an integral method measuring changes in size and density or rather their distribution has advantages over determining particle size distribution only. It is given with the separation velocity distribution.

Reference: bit.ly/2mqFeyk

![]() Hansen Solubility Parameters

Hansen Solubility Parameters

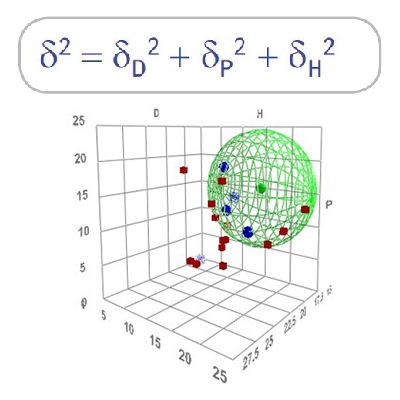

Hansen Parameters (HSPs) - in most recent publications named Hansen Dispersibility Parameters - have been widely used in diverse scientific disciplines and industries for predicting the solubility of materials in different solvents and for characterization of pigment dispersibility and wettability of various surfaces as well as of adsorption properties of pigment surfaces.

Using the 3D-Hansen space approach, particles are dispersed into a number of liquids. Based on their behavior - good or bad homogeneous distribution, extent of agglomeration or flocculation – liquids are ranked as "Good" or "Bad". The LUMiReader PSA can be applied to determine Standardized Relative Sedimentation Time (RST) as base for ranking solvents as good or bad, especially in case of fast settling.

Reference: bit.ly/2lmjHXA